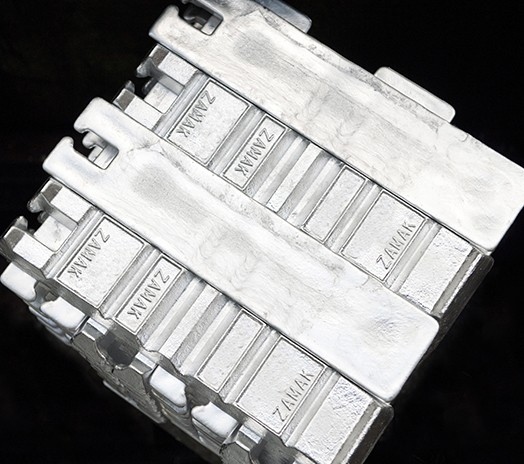

ZL0430 / ZnAl4Cu3 / Zamak 2

Zamak 2

Zamak 2 has the same composition as zamak 3 with the addition of 3% copper in order to increase strength by 20%, which also increases the price

Zamak 2 has the greatest strength out of all the zamak alloys. Over time it retains its strength and hardness better than the other alloys; however, it becomes more brittle, shrinks, and less elastic.

Zamak 2 is also known as Kirksite when gravity cast for use as a die. It was originally designed for low volume sheet metal dies. It later gained popularity for making short run injection molding dies. It is also less commonly used for non-sparking tools and mandrels for metal spinning.

Zamak 2 is the highest strength and hardness of the Zamak family. This alloy has excellent casting characteristics including:

Zamak 2 (EN1774 European Standard) Chemical Analysis

| Analysis (EN1774) ( %) | Zamak 2 / ZL0430 / ZnAl4Cu3 |

|---|---|

| Al | 3.8 – 4.2 |

| Cu | 2.7 – 3.3 |

| Mg | 0.035 – 0.06 |

| Pb | ≤0.003 |

| Fe | ≤0.02 |

| Cd | ≤0.003 |

| Sn | ≤0.001 |

| Si | ≤0.02 |

| Ni | ≤0.001 |

Zamak 2 General Mechanical Properties

| Mechanical Properties | Metric Value |

|---|---|

| Ultimate Tensile Strength | 397 MPa (331 MPa aged) |

| Yield Strength | 361 MPa |

| Impact Strength | 38 J (7 J aged) |

| Elongation at Fmax | 3% (2% aged) |

| Elongation at Fracture | 6% |

| Shear Strength | 317 MPa |

| Compressive Yield Strength | 641 MPa |

| Fatigue Strength (reverse bending 5×108cycles) | 59 MPa |

| Hardness | 130 Brinell (98 Brinell aged) |

| Modulus of Elasticity | 96 GPa |

Zamak 2 General Physical Properties

| Physical Properties | Metric Value |

|---|---|

| Solidification Range (melting range) | 379—390 °C |

| Density | 6.8 kg/dm3 |

| Coefficient of Thermal Expansion | 27.8 μm/m-°C |

| Thermal Conductivity | 105 W/mK |

| Electrical Resistivity | 6.85 μΩ-cm at 20 °C |

| Latent Heat (heat of fusion) | 110 J/g |

| Specific Heat Capacity | 419 J/kg-°C |

| Coefficient of Friction | 0.08 |